The Working Principle of Direct Acting Solenoid Valves

At the heart of a

Direct Acting Solenoid Valve is the solenoid coil. The coil consists of a wire wound into a cylindrical shape, and when an electrical current flows through it, it generates a magnetic field. The strength of this magnetic field depends on the amount of current passing through the coil and the number of turns in the wire. The principle is based on Ampère's Law, which states that a current-carrying conductor generates a magnetic field around it. Yuyao Spring Water Filter Equipment Co., Ltd.'s solenoid coils are designed for optimal efficiency, ensuring that even at low current levels, a strong and reliable magnetic field is produced. The high-quality materials used in these coils allow them to function efficiently over an extended period, ensuring the valve’s durability and minimizing the risk of coil failure.

The magnetic field created by the solenoid coil attracts a movable metallic component known as the armature. The armature, which is typically a cylindrical or spherical metal part, is connected to a plunger—a rod-like structure that can move within the valve body. When the solenoid coil is energized, the magnetic field generated exerts a force on the armature, causing it to move. This movement is what actuates the valve, either opening or closing it depending on the design of the valve. The plunger is seated within a valve orifice, blocking the flow of fluid or gas when the valve is closed. When the solenoid is energized, the armature moves, lifting the plunger and opening the valve to allow the fluid or gas to pass through. In contrast, when the solenoid is de-energized, the armature is released, and the plunger is returned to its seated position by a spring or gravity, closing the valve and halting the flow. Yuyao Spring Water Filter Equipment Co., Ltd.'s Direct Acting Solenoid Valves are known for their fast response times and precision in this phase of operation. The company employs high-grade materials for the armature and plunger to ensure they respond to the magnetic field with speed and accuracy. This precision is crucial in applications that require quick shut-off or regulation of fluid flow, such as in water filtration systems or industrial automation.

The flow of the fluid or gas through the valve is regulated by the position of the plunger. When the plunger is seated against the valve body, it creates a seal that prevents the passage of fluid or gas, effectively closing the valve. The seal must be tight to prevent leakage, and the design of the valve seat ensures that the plunger makes consistent contact to create this barrier. When the solenoid is energized and the armature moves, the plunger is lifted from the valve seat, allowing fluid or gas to flow through the valve's orifice. The size of the orifice and the movement of the plunger determine the rate of flow, offering precise control over fluid movement. The efficiency of this mechanism is largely determined by the precision of the plunger movement and the sealing capability of the valve seat, both of which are features that Yuyao Spring Water Filter Equipment Co., Ltd. focuses on in their valve design and manufacturing process.

Once the solenoid is de-energized, the magnetic field collapses, and the armature is no longer attracted to the coil. The plunger then returns to its closed position, typically with the assistance of a spring or gravity. The spring pushes the plunger back into the valve seat, sealing the orifice and stopping the flow of fluid. Yuyao Spring Water Filter Equipment Co., Ltd. uses high-quality springs in their Direct Acting Solenoid Valves to ensure the smooth and reliable return of the plunger to its seat. The strength of the spring is carefully calibrated to match the forces generated by the solenoid, ensuring that the valve closes effectively and consistently every time.

The direct acting design of the solenoid valve offers several advantages over other types of valves, particularly in terms of responsiveness, size, and reliability. Since Direct Acting Solenoid Valves do not rely on external pressure to function, they can operate in a broader range of conditions, including those where the incoming pressure is low or fluctuates. This makes them ideal for applications where precise control of flow is essential, such as in microfluidic systems, medical devices, or water filtration systems. The direct acting mechanism also allows for a more compact valve design. Since the valve does not need to incorporate a diaphragm or other external components to assist in operation, the size of the valve can be reduced, making it suitable for installation in tight spaces. This feature is particularly valuable in industries where space constraints are a concern. Yuyao Spring Water Filter Equipment Co., Ltd. capitalizes on these advantages by designing their Direct Acting Solenoid Valves to be compact, efficient, and reliable. Their valves can be used in a variety of systems, from water filtration to complex industrial applications, without sacrificing performance.

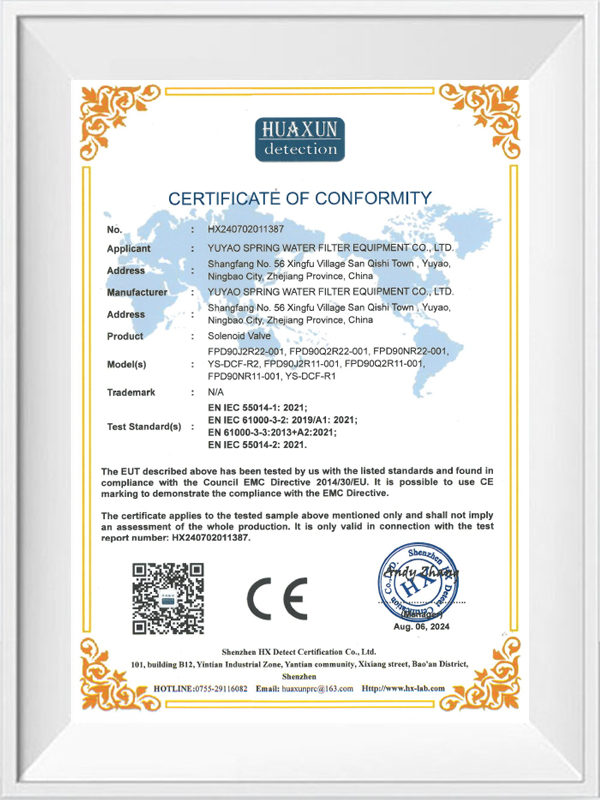

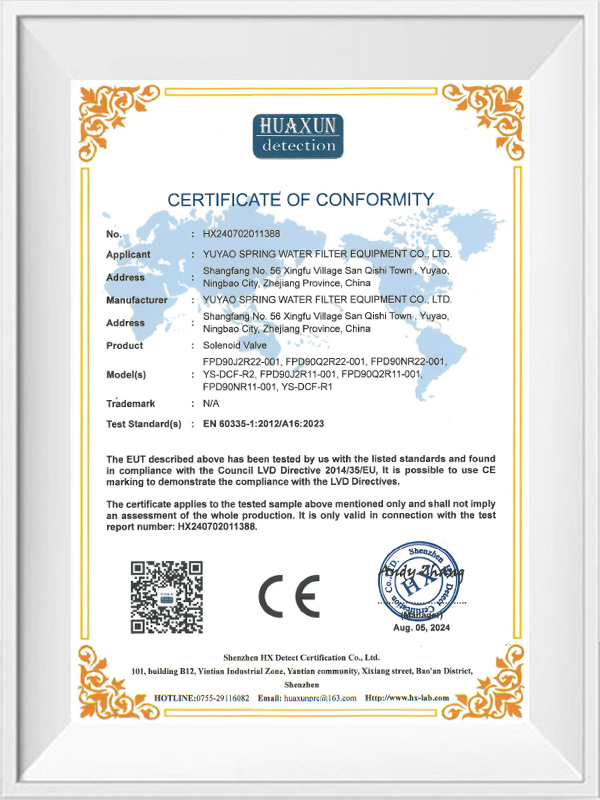

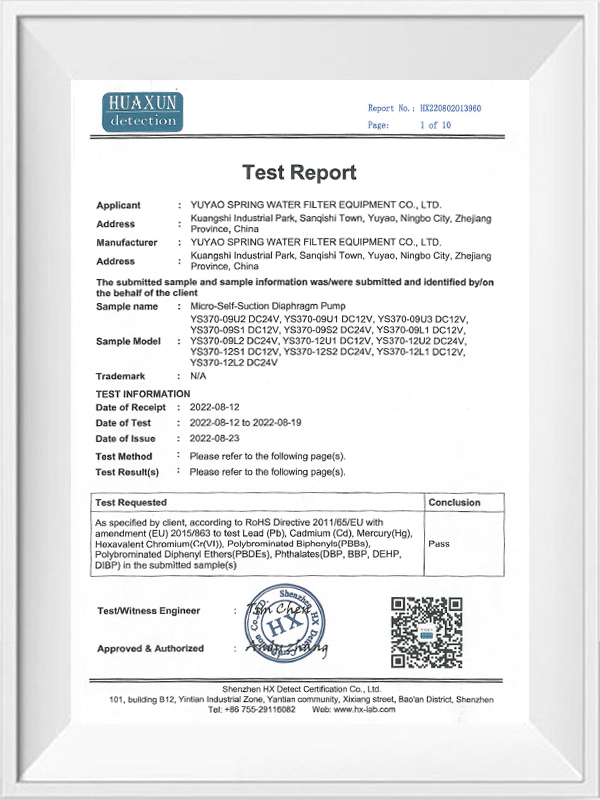

Direct Acting Solenoid Valves are versatile components that are used across a range of industries. In water treatment systems, they regulate the flow of water through filtration units, ensuring that only clean water is allowed to pass through. These valves are also critical in industrial automation, where they control the flow of air, gases, and liquids in manufacturing processes. In the automotive industry, Direct Acting Solenoid Valves are used for fuel injection systems, airbag deployment mechanisms, and emission control systems. Yuyao Spring Water Filter Equipment Co., Ltd. specializes in designing and manufacturing solenoid valves for such applications, ensuring that their valves meet the specific requirements of each industry. With a strong commitment to quality and innovation, the company has earned a reputation for providing reliable, durable, and high-performance solenoid valves to clients across the world.

English

English 中文简体

中文简体